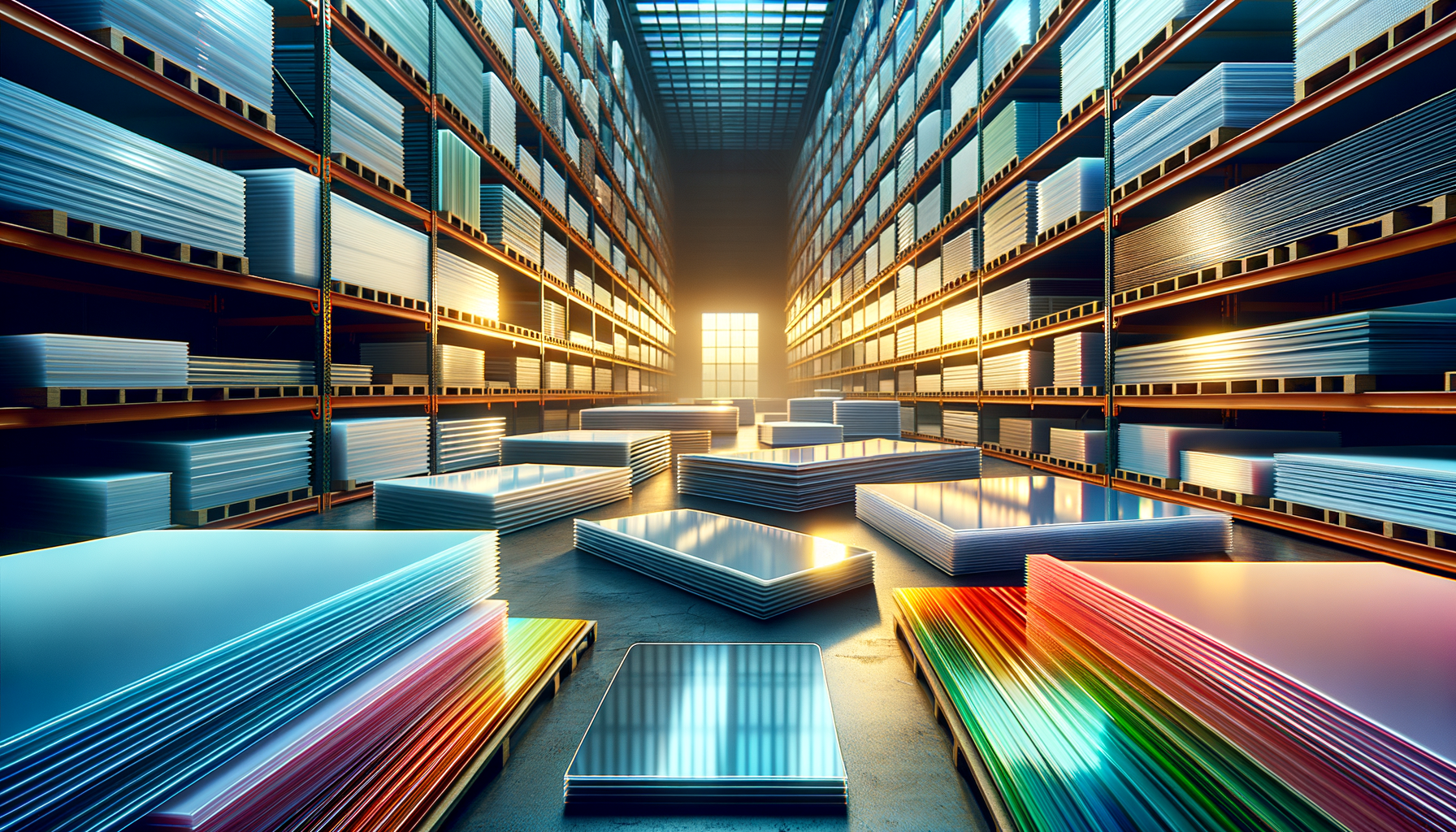

Understanding Polycarbonate Sheets

Polycarbonate sheets are a type of thermoplastic material known for their high impact resistance and optical clarity. This material is often used in applications where glass would traditionally be used, but where additional durability is required. Polycarbonate sheets are lightweight yet incredibly strong, making them suitable for a range of uses from greenhouse glazing to protective barriers. The sheets are available in various thicknesses, offering flexibility depending on the specific needs of a project. Their ability to withstand extreme temperatures and resist UV radiation makes them a popular choice for outdoor applications.

Advantages of Using Polycarbonate Sheets

The benefits of polycarbonate sheets are numerous, making them an attractive option for both commercial and residential projects. Some key advantages include:

- Durability: Polycarbonate sheets are virtually unbreakable, providing a level of safety and security that glass cannot match.

- Lightweight: Despite their strength, these sheets are much lighter than glass, making installation easier and reducing structural load.

- Thermal Insulation: The material offers excellent thermal insulation properties, which can lead to energy savings in heating and cooling.

- UV Protection: Many polycarbonate sheets come with a UV protective layer, extending the life of the material and protecting against sun damage.

- Flexibility: Polycarbonate can be easily cut and shaped, allowing for custom designs and applications.

These features make polycarbonate sheets a versatile and practical choice for various applications, from industrial to residential settings.

Common Applications of Polycarbonate Sheets

Polycarbonate sheets have found their way into a multitude of industries due to their versatile nature. In the construction industry, they are widely used for roofing, skylights, and cladding due to their ability to transmit light while providing insulation. Greenhouses often utilize polycarbonate sheets because they allow sunlight to penetrate while maintaining a controlled environment for plant growth. In the realm of safety and protection, these sheets are used in the manufacturing of eyewear lenses, protective shields, and even bulletproof windows. The automotive industry also benefits from polycarbonate’s properties, using it for headlamp lenses and interior components. The diverse applications of polycarbonate sheets highlight their adaptability and effectiveness across different fields.

Comparing Polycarbonate Sheets with Other Materials

When choosing materials for construction or manufacturing, it’s essential to compare the options available. Polycarbonate sheets stand out against traditional materials like glass and acrylic for several reasons. Compared to glass, polycarbonate is more impact-resistant and lighter, providing a safer and more manageable alternative. Unlike acrylic, polycarbonate offers better thermal insulation and higher impact resistance, making it a more durable choice. While acrylic may offer slightly better optical clarity, polycarbonate’s strength and flexibility often outweigh this factor. Additionally, polycarbonate’s ability to withstand higher temperatures and its inherent UV resistance make it a superior choice for outdoor applications.

Choosing the Right Polycarbonate Sheet for Your Needs

Selecting the appropriate polycarbonate sheet involves considering several factors to ensure it meets the specific requirements of your project. First, determine the thickness needed based on the application and the level of impact resistance required. Consider whether a clear or tinted sheet is more suitable, depending on the desired light transmission and aesthetic effect. For outdoor applications, ensure the sheets have a UV protective coating to extend their lifespan. It’s also essential to evaluate the environmental conditions the sheets will be exposed to, such as temperature fluctuations and potential chemical exposure. By carefully assessing these factors, you can choose the polycarbonate sheet that best suits your needs, ensuring durability and effectiveness in its application.

Leave a Reply