Introduction to Gas Detection Systems

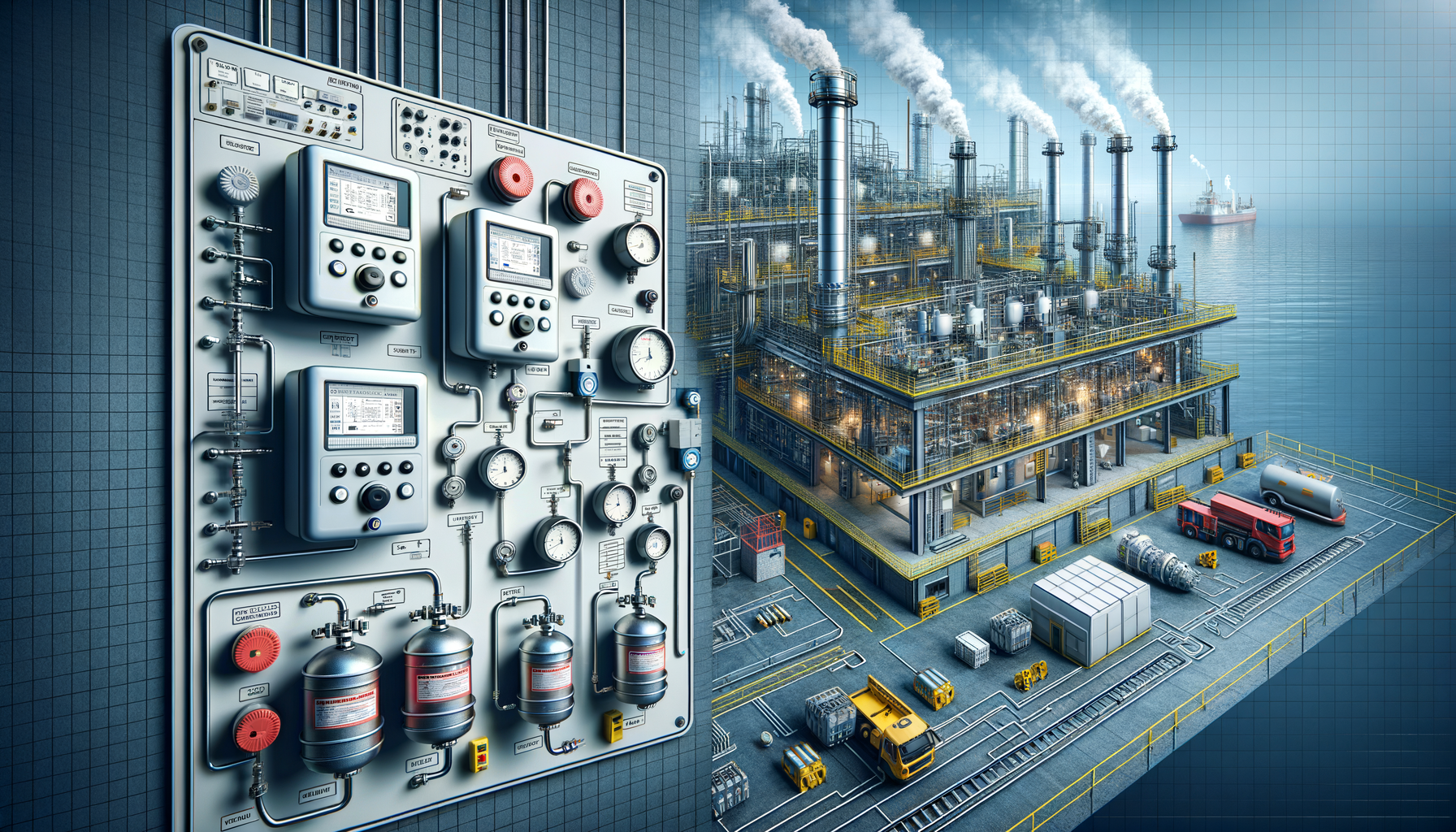

In various industrial settings, the presence of hazardous gases can pose significant risks to both workers and the environment. Gas detection systems play a crucial role in ensuring safety by identifying potentially dangerous gas leaks before they lead to accidents or health hazards. These systems are indispensable in industries such as oil and gas, manufacturing, and mining, where the release of toxic or flammable gases can have severe consequences. Understanding how these systems work and their importance in workplace safety is vital for any organization aiming to maintain a safe working environment.

Types of Gas Detectors

Gas detectors come in various types, each designed to detect specific gases or a range of gases. The most common types include:

- Electrochemical Gas Detectors: These are widely used for detecting toxic gases such as carbon monoxide and hydrogen sulfide. They operate by producing a chemical reaction between the gas and a sensor that generates an electrical signal proportional to the gas concentration.

- Infrared Gas Detectors: Ideal for detecting flammable gases, these detectors use infrared sensors to identify gas presence based on the absorption of infrared light.

- Catalytic Bead Gas Detectors: Often used for combustible gases, they work by oxidizing the gas at a catalytic bead, causing a change in temperature that is converted into a readable signal.

- Photoionization Detectors (PIDs): These are used for volatile organic compounds (VOCs) and some toxic gases, measuring the ionization of gas molecules by ultraviolet light.

Each type of detector has its own advantages and limitations, making it crucial to choose the right one based on the specific gases present in the workplace.

Importance of Gas Detection Systems in Workplace Safety

The implementation of gas detection systems is a proactive approach to preventing accidents and ensuring worker safety. These systems provide real-time monitoring and alert personnel to the presence of hazardous gases, allowing for immediate action to mitigate risks. Key benefits of using gas detection systems include:

- Early Warning: Gas detectors provide early warnings, enabling quick evacuation or intervention to prevent health hazards or explosions.

- Compliance with Regulations: Many industries are subject to strict regulations regarding air quality and safety. Gas detection systems help ensure compliance with these standards.

- Protection of Assets: By preventing gas-related incidents, these systems help protect valuable equipment and infrastructure from damage.

- Environmental Safety: Detecting gas leaks early minimizes the environmental impact of hazardous emissions.

Overall, gas detection systems are an essential component of a comprehensive safety strategy in any industrial setting.

Choosing the Right Gas Detection System

Selecting the appropriate gas detection system involves several considerations to ensure it meets the specific needs of the workplace. Factors to consider include:

- Type of Gases: Identify the specific gases present in the workplace to choose a detector capable of accurately detecting them.

- Detection Range: Ensure the system can detect gas concentrations at levels that are relevant to the safety standards of the industry.

- Environment: Consider the environmental conditions, such as temperature and humidity, which can affect the performance of gas detectors.

- Integration: Determine if the gas detection system needs to integrate with existing safety systems or require remote monitoring capabilities.

By evaluating these factors, organizations can implement a gas detection system that effectively enhances workplace safety and complies with industry regulations.

Maintaining and Calibrating Gas Detectors

Regular maintenance and calibration of gas detectors are critical to ensure their accuracy and reliability. Over time, sensors can drift or become less sensitive, leading to potential safety risks. Key maintenance practices include:

- Scheduled Calibration: Perform regular calibration using known gas concentrations to adjust the detector’s readings and ensure accuracy.

- Routine Inspections: Conduct visual and functional inspections to check for any physical damage or malfunctions.

- Sensor Replacement: Replace sensors as recommended by the manufacturer to maintain optimal performance.

- Record Keeping: Maintain detailed records of maintenance activities, calibrations, and any issues encountered with the detectors.

By adhering to these maintenance practices, organizations can ensure their gas detection systems remain effective in protecting workers and the environment from gas-related hazards.

Conclusion: Enhancing Safety with Gas Detection Systems

Gas detection systems are a vital component of workplace safety, providing early warnings and enabling swift action to prevent accidents and health hazards. By understanding the types of gas detectors, their importance, and how to choose and maintain them, organizations can create a safer working environment. Investing in reliable gas detection systems not only protects workers but also ensures compliance with regulations and safeguards assets. Ultimately, these systems are an essential part of any comprehensive safety strategy in industrial settings.

Leave a Reply