The Rise of Metal Sandwich Panels in Construction

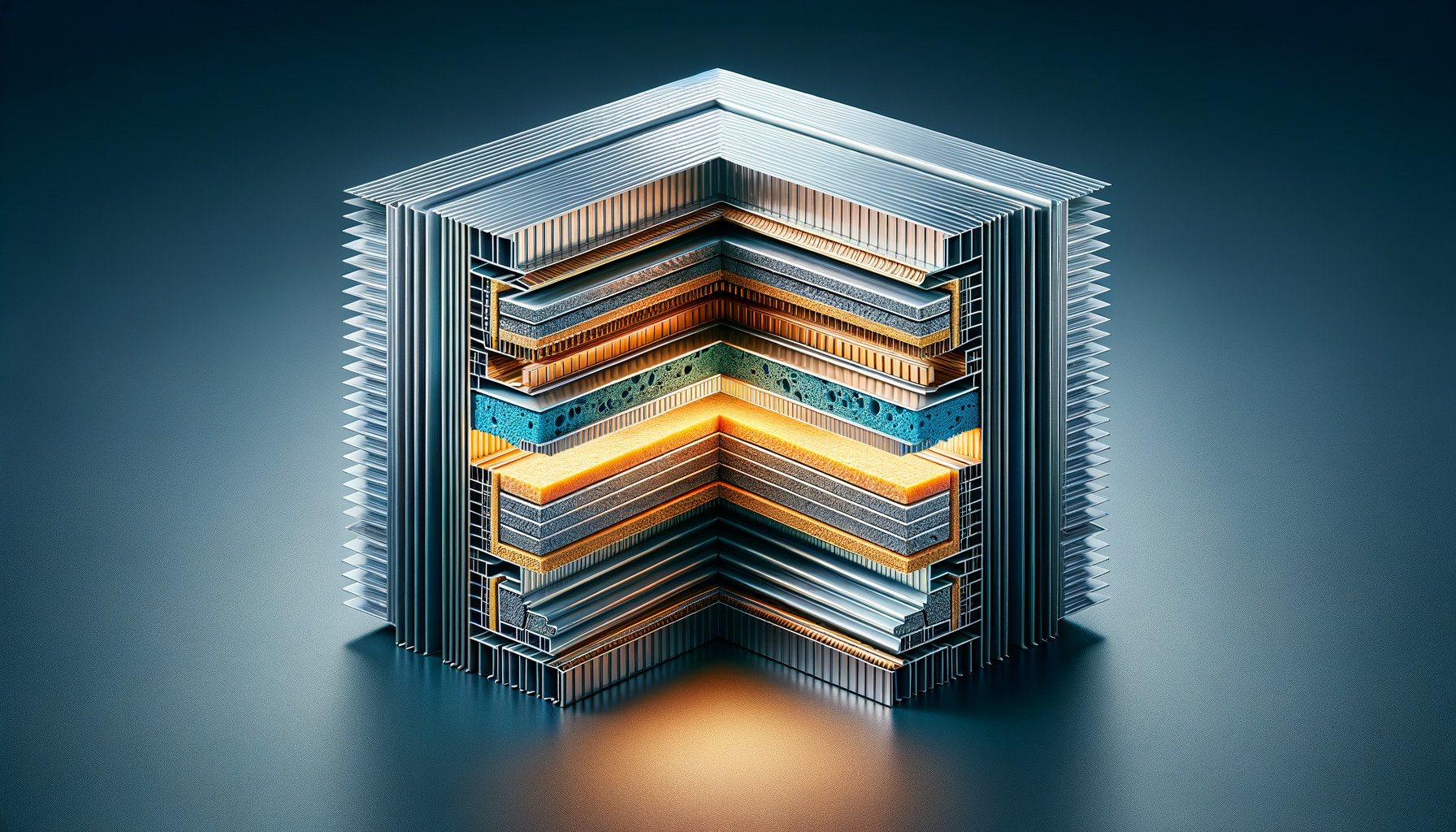

Metal sandwich panels have emerged as a revolutionary material in the construction industry, offering a blend of strength, insulation, and aesthetic appeal. These panels consist of two metal sheets with an insulating core in between, typically made of materials like polyurethane, polystyrene, or mineral wool. Their popularity has surged due to their versatility and efficiency, making them a preferred choice for both residential and commercial projects.

One of the key advantages of metal sandwich panels is their ability to provide excellent thermal insulation. This feature is particularly beneficial in climates with extreme temperatures, as it helps maintain a stable indoor environment, reducing the need for excessive heating or cooling. Additionally, the panels are lightweight yet sturdy, which simplifies transportation and installation, reducing labor costs and time.

Moreover, these panels are renowned for their durability and resistance to environmental factors such as moisture, pests, and fire. This makes them a sustainable option, as they require minimal maintenance and have a long lifespan. The aesthetic flexibility of metal sandwich panels also allows architects to explore innovative designs, contributing to their growing adoption in modern architecture.

Applications and Benefits in Various Sectors

Metal sandwich panels are utilized across a wide range of sectors, each benefiting from their unique properties. In the commercial sector, they are commonly used for constructing warehouses, factories, and cold storage facilities due to their excellent insulation and structural integrity. The panels help maintain controlled environments essential for preserving goods and materials.

In residential construction, metal sandwich panels are increasingly being used for roofing and cladding, providing homeowners with energy-efficient and aesthetically pleasing solutions. The panels’ ability to reflect sunlight and insulate homes contributes to lower energy bills, making them an economically attractive option.

Beyond construction, these panels are also employed in the transportation industry, particularly in refrigerated trucks and containers. Their lightweight nature and insulating properties make them ideal for maintaining temperatures during transit, ensuring the safe delivery of perishable goods.

The versatility of metal sandwich panels extends to their environmental benefits. They are often manufactured using recyclable materials, aligning with sustainable building practices. This not only reduces the carbon footprint of construction projects but also supports the global push towards eco-friendly development.

Comparing Metal Sandwich Panels with Traditional Materials

When comparing metal sandwich panels to traditional building materials such as wood, concrete, and brick, several distinct advantages become apparent. While traditional materials have their merits, metal sandwich panels offer superior insulation and weight advantages. For instance, the lightweight nature of these panels reduces the overall structural load, which can lead to cost savings in foundation and structural support.

In terms of thermal performance, metal sandwich panels excel due to their insulating core, which significantly reduces heat transfer. This is a stark contrast to materials like concrete and brick, which require additional insulation layers to achieve similar thermal efficiency. Furthermore, the installation process for metal sandwich panels is often quicker and more straightforward, as they can be prefabricated to specific dimensions, reducing on-site labor.

Another significant advantage is the panels’ resistance to environmental conditions. Unlike wood, which can be susceptible to rot and pest infestation, metal sandwich panels offer robust protection against such issues. This not only enhances the longevity of the structure but also reduces ongoing maintenance costs.

While the initial cost of metal sandwich panels may be higher than some traditional materials, the long-term savings in energy efficiency, maintenance, and installation time often justify the investment. This makes them an appealing option for projects where durability and sustainability are priorities.

Innovations and Future Trends in Metal Sandwich Panel Technology

The field of metal sandwich panels is continuously evolving, with ongoing research and development aimed at enhancing their performance and applications. Innovations in core materials, for example, are leading to panels with even better insulation properties and fire resistance. Researchers are exploring advanced materials like aerogels and vacuum insulation panels to further improve thermal efficiency.

Another exciting trend is the integration of smart technologies into metal sandwich panels. This includes the incorporation of sensors and IoT (Internet of Things) devices to monitor structural health and energy performance in real-time. Such advancements could revolutionize building management systems, allowing for more efficient energy use and maintenance scheduling.

In terms of aesthetics, manufacturers are developing panels with customizable finishes and textures, enabling architects to achieve specific design goals without compromising on functionality. This trend is particularly relevant in urban settings, where the visual impact of buildings is a significant consideration.

As sustainability becomes a central focus in construction, the demand for recyclable and eco-friendly materials is expected to drive further innovation in metal sandwich panels. The industry is likely to see a surge in the use of renewable energy sources in the manufacturing process, reducing the environmental impact of these products.

Conclusion: The Future of Construction with Metal Sandwich Panels

Metal sandwich panels represent a significant advancement in construction materials, offering a harmonious blend of insulation, durability, and design flexibility. Their application across various sectors demonstrates their versatility and effectiveness in addressing modern construction challenges. As the industry continues to prioritize sustainability and energy efficiency, the role of metal sandwich panels is poised to expand, paving the way for greener and more resilient buildings.

For builders, architects, and developers, understanding the benefits and potential of metal sandwich panels is crucial in making informed decisions that align with both economic and environmental goals. As innovations continue to emerge, these panels will likely remain at the forefront of construction technology, shaping the future of the built environment.

Leave a Reply