Introduction to Laser Cutting Technology

Laser cutting technology has revolutionized the manufacturing and design industries with its precision and versatility. Utilizing a high-powered laser beam, this technology can cut through a variety of materials with exceptional accuracy, making it a preferred choice for many applications. The importance of laser cutting lies in its ability to produce intricate designs and complex shapes that would be challenging to achieve with traditional cutting methods. This technology is not only about cutting but also about enhancing the efficiency and quality of the final product.

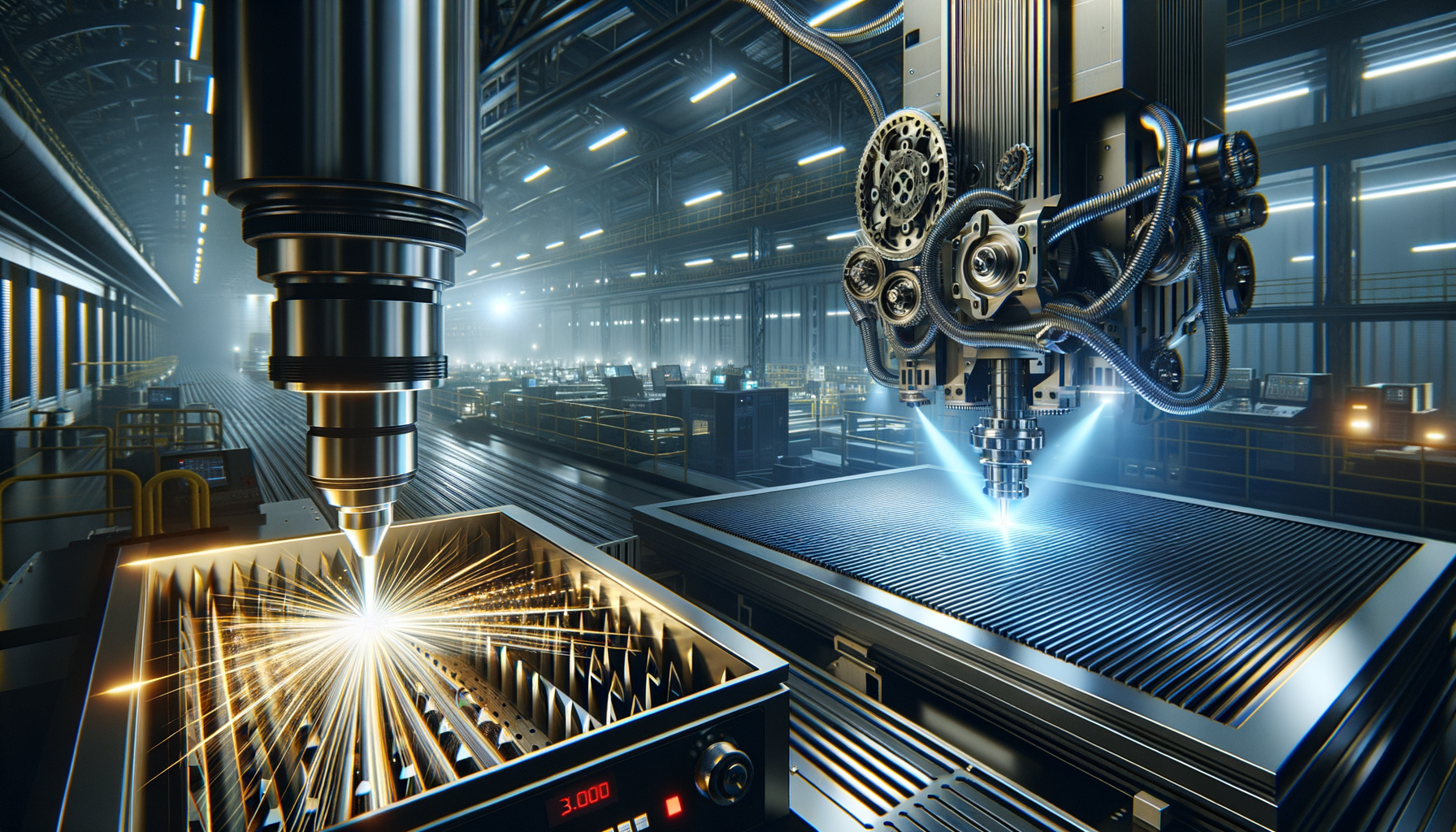

How Laser Cutting Works

At the heart of laser cutting technology is the laser beam, which is focused onto the material to melt, burn, or vaporize it away. The process begins with the generation of a laser beam through the stimulation of lasing material inside a laser resonator. This beam is then directed towards the material using mirrors or fiber optics. The precision of laser cutting is achieved by controlling the intensity, length, and heat output of the laser beam.

There are several types of lasers used in cutting, including CO2 lasers, fiber lasers, and neodymium lasers. Each type has its own set of advantages and is suited for different materials. For example, CO2 lasers are commonly used for cutting non-metal materials like wood and acrylic, while fiber lasers are ideal for cutting metals due to their high power and efficiency.

- CO2 Lasers: Suitable for non-metal materials

- Fiber Lasers: Efficient for metal cutting

- Neodymium Lasers: Used for high power applications

The precision and speed of laser cutting make it an outstanding choice for industries that require high accuracy and efficiency.

Applications of Laser Cutting

Laser cutting technology finds applications across a wide range of industries, each benefiting from its precision and versatility. In the automotive industry, laser cutting is used to create intricate parts and components, ensuring high precision and reducing waste. The aerospace industry relies on laser cutting for the fabrication of complex parts that require stringent tolerances.

In the fashion and textile industry, laser cutting is used to create detailed patterns and designs on fabrics, enhancing creativity and reducing production time. The technology is also prevalent in the electronics industry, where it is used to cut and shape circuit boards with precision.

Other notable applications include:

- Medical Device Manufacturing: Precise cutting of components

- Jewelry Making: Intricate designs and patterns

- Architectural Models: Detailed and accurate scale models

The versatility of laser cutting technology continues to expand its applications, making it an invaluable tool in modern manufacturing and design.

Advantages and Disadvantages of Laser Cutting

Laser cutting technology offers numerous advantages that make it a preferred choice for many industries. One of the primary benefits is its precision, allowing for the creation of intricate designs with minimal material waste. The speed of laser cutting is another advantage, significantly reducing production times compared to traditional methods.

However, laser cutting also has its limitations. The initial cost of laser cutting machines can be high, which may be a barrier for small businesses. Additionally, while laser cutting is suitable for many materials, it may not be the best choice for very thick materials or certain reflective metals.

Advantages of Laser Cutting:

- High Precision: Accurate and detailed cuts

- Speed: Faster production times

- Versatility: Suitable for a variety of materials

Disadvantages of Laser Cutting:

- High Initial Cost: Expensive equipment

- Material Limitations: Not suitable for very thick materials

Despite these disadvantages, the benefits of laser cutting often outweigh the limitations, making it a valuable technology in many sectors.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is promising, with ongoing advancements aimed at enhancing its capabilities and efficiency. One of the key trends is the development of more powerful and efficient lasers that can cut through thicker materials and improve cutting speeds. Additionally, the integration of automation and artificial intelligence is expected to streamline laser cutting processes, reducing human intervention and increasing precision.

Another trend is the growing use of laser cutting in emerging industries such as renewable energy and electric vehicles, where precision and efficiency are crucial. The technology is also expected to play a significant role in the development of smart manufacturing systems, contributing to the Industry 4.0 revolution.

Future trends to watch:

- Advancements in Laser Power: Cutting thicker materials

- Automation and AI Integration: Enhanced precision and efficiency

- Expansion into New Industries: Renewable energy and electric vehicles

As laser cutting technology continues to evolve, it will undoubtedly open up new possibilities and applications, further cementing its importance in the modern industrial landscape.

Leave a Reply