Learn about Swimming Pool Installation

Outline: How This Guide Leads You from Idea to Filled Pool

Before concrete is poured or a fiberglass shell is craned in, success starts with a plan. This guide is structured to move you from concept to completion with clarity. First, you’ll scan an overview of what matters most: regulations, design choices, construction steps, and long-term ownership. Then, you’ll tour the major pool types and finishes, see what they cost, and learn how they perform over time. After that, we’ll walk through the build sequence so you know what to expect week by week, including the hidden work beneath the waterline. Finally, we close with maintenance, energy use, and value—because a pool is a project and a lifestyle. Consider this your roadmap, annotated with real-world tips to help you avoid delays and surprises.

Here’s what each part covers and why it matters to you as a homeowner, designer, or property manager:

– Planning, Design, and Permits: How to align your budget and layout with local codes, safety, and site conditions.

– Types, Materials, and Features: A plain-English comparison of concrete, fiberglass, and vinyl—durability, timelines, and upkeep included.

– Construction Step by Step: From excavation and steel to plumbing, electrical, waterproofing, and decking, with quality checks along the way.

– Ownership, Maintenance, and ROI: Energy choices, water chemistry basics, annual costs, and how a pool can influence property value.

Throughout the guide, you’ll find pragmatic data points. Typical permit windows range from 2–8 weeks depending on jurisdiction and whether variances are needed. Average installation timelines vary widely by method—roughly 2–4 weeks for many fiberglass projects versus 8–12+ weeks for concrete. Annual operating costs often land between a few hundred and a few thousand dollars, depending on climate, energy rates, and usage patterns. We weave in these benchmarks not to lock you into a number, but to help you ask the right questions and plan with confidence.

Most important, the sections build on each other. Getting the site plan and approvals right reduces change orders. Choosing materials that suit your soil, weather, and schedule avoids costly midstream pivots. Understanding the build sequence helps you spot shortcuts before they cure into concrete. And clear maintenance habits protect your investment. With the map in hand, let’s start at the beginning.

Planning, Design, and Permits: Setting a Solid Foundation

Great pools begin long before excavation. Start with goals: exercise laps, family play, quiet lounging, or resale appeal. Those aims shape dimensions, depth profile, and features like benches, baja shelves, or swim lanes. Walk your yard at different times of day and note sun paths, shadows from trees or structures, wind direction, and privacy lines. Sunlight affects water temperature and algae growth; wind influences evaporation and heat loss. If you can, sketch two or three concept layouts and consider how paths, doors, and sightlines from the house connect to the water and deck.

Next, study your site. Call to locate underground utilities. Check easements and setbacks—many codes require minimum distances from property lines, septic systems, and overhead lines. Soil matters: sandy soils drain quickly and can shift; expansive clays swell and shrink; high water tables demand hydrostatic relief strategies. A simple soil report can save thousands by guiding excavation and base prep. For sloped lots, consider terraced decks, retaining walls, or a semi-recessed design that works with the grade rather than fighting it.

Permits and safety rules are nonnegotiable. Expect plan submittals showing pool dimensions, barriers, gates, anti-entrapment drain details, bonding/grounding, and sometimes engineering for structural loads. Many regions require self-closing, self-latching gates and specific fence heights. Timelines vary, but 2–8 weeks is common; add time if you need zoning relief. Inspections typically occur at several milestones: excavation/steel, underground plumbing/electrical, pre-deck, and final. Scheduling inspectors early reduces downtime between phases.

Budgeting should reflect the full project, not just the shell. Include deck surfaces, drainage, lighting, a cover, fencing, landscaping, and any retaining walls. Keep a contingency of 10–15% for unknowns like rock removal or weather delays. A practical planning checklist could look like this:

– Define purpose and size ranges, including depth changes and steps.

– Map setbacks, utilities, sun/wind exposure, and neighbor views.

– Select a preliminary pool type to anchor cost and schedule.

– Assemble documents for permits; confirm inspection milestones.

– Align financing, contingency, and seasonal timing to avoid rushing.

Finally, timing matters. In many climates, starting design and permits in late winter positions construction for spring, leaving time for decking, landscaping, and warm-weather commissioning. Enter the process with a clear plan, and the rest of the journey becomes far smoother.

Types, Materials, and Features: Matching a Pool to Your Priorities

Choosing the construction method is the biggest fork in the road. In-ground concrete (shotcrete or cast-in-place) offers custom shapes, deep ends, and complex features. It is highly durable—shells commonly last decades with proper care—but requires longer build times and periodic surface refinishing. Fiberglass arrives as a factory-molded shell, lowering installation time and providing a smooth, nonporous surface that resists algae. You’ll choose from predefined shapes and sizes, which can streamline decisions but limit complete customization. Vinyl-liner pools use a framed structure and a fitted liner that delivers a pleasant feel underfoot and can be cost-efficient upfront; expect liner replacements over the years as part of normal ownership.

Consider these practical trade-offs and typical ranges, which vary by region and complexity:

– Concrete: flexible design, robust for diving wells and integrated spas; commonly 8–12+ weeks; periodic resurfacing (often 10–20 years depending on finish and chemistry).

– Fiberglass: faster installations (frequently 2–4 weeks once permits are cleared), smooth finish, limited to factory sizes; careful access needed for crane delivery.

– Vinyl liner: approachable upfront price, soft feel, easily repaired liners; liners typically last 7–12 years depending on UV exposure and water balance.

Costs reflect scope. Beyond the shell, account for decking, coping, water features, automation, and safety covers. As a broad orientation, above-ground options can be relatively economical and quick to assemble, while in-ground projects vary widely with soil conditions, access, and finish choices. Long-term cost of ownership also matters: nonporous finishes can reduce brushing and chemical demand, while darker interiors may warm faster in sunny climates but show scale more readily.

Features and finishes shape the experience. Entry systems (full-width steps, baja shelves) suit families and lounging. Benches and ledges add usable space without expanding the footprint. For finishes, plaster, quartz blends, and exposed aggregates each change texture, color depth, and maintenance profiles. Tile lines reduce ring staining and make routine cleaning easier. Coping options—poured-in-place concrete, natural stone, or precast units—affect both aesthetics and heat retention underfoot. Lighting upgrades extend evening use and improve safety; low-glare, warm color temperatures create a relaxed feel.

Water treatment is another key decision. Traditional chlorination is familiar and effective, while salt-chlorine generators produce chlorine on-site from salt, softening the feel and moderating handling of tablets. Regardless of system, aim to keep pH around 7.2–7.8 and free chlorine within the manufacturer’s recommended range; a cover reduces UV loss and evaporation, stretching each dose further. Think holistically: the right pairing of structure, finish, and equipment lowers work, energy, and surprises over the pool’s lifespan.

Construction Step by Step: From Groundwork to First Splash

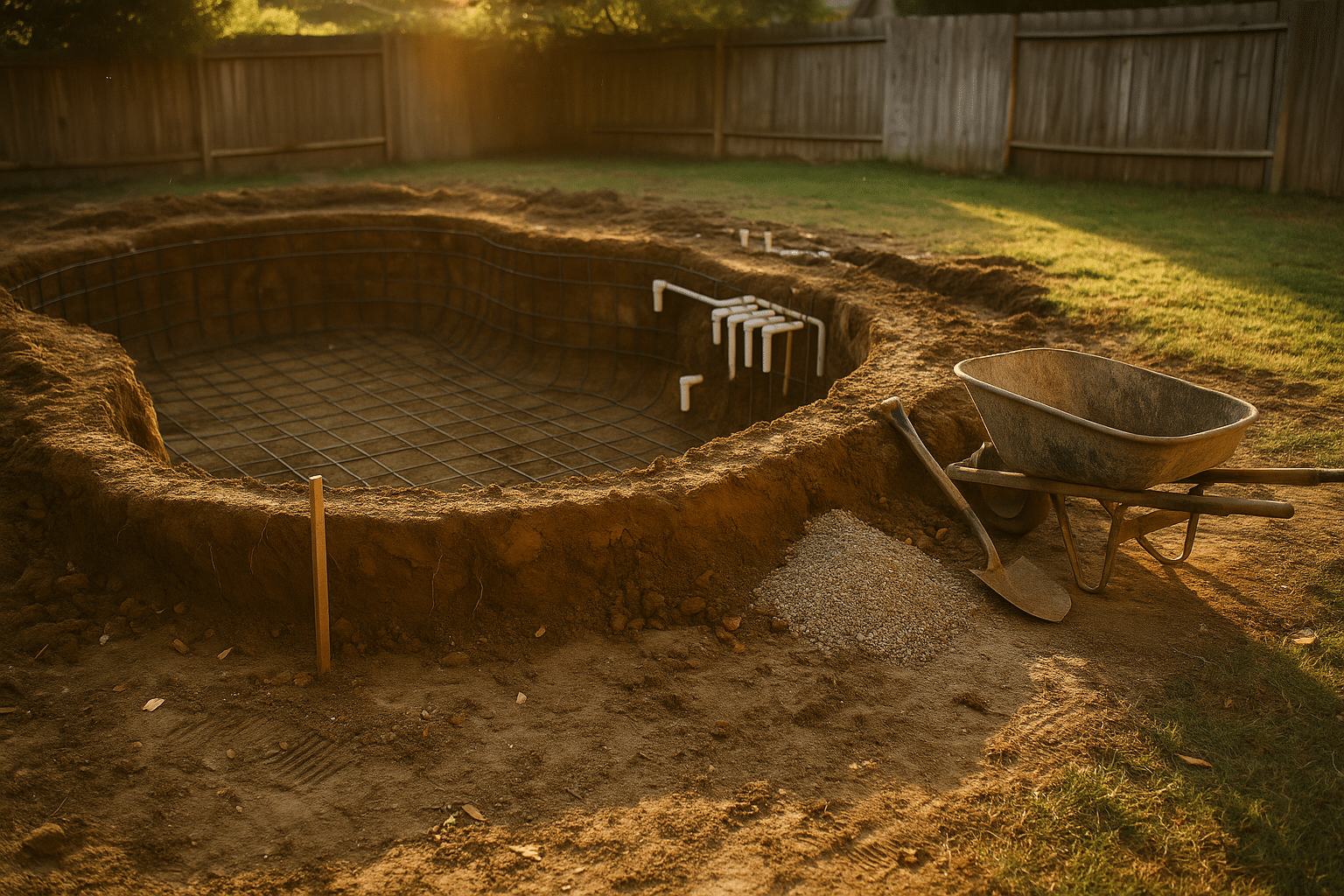

Once permits are in hand, the site is staked, elevations are checked, and protective fencing goes up. Excavation begins with overdig to allow for base material and forms. Expect surprises like buried debris or rock; contingency funds and time help here. The base is compacted, sometimes with a gravel layer for drainage. For concrete pools, steel reinforcement is tied to engineer specifications, shaping walls, steps, and benches. Fiberglass installations set and level the shell on a prepared bed, then backfill in lifts while filling the pool to keep pressures balanced. Vinyl projects assemble the wall system, set the floor, and pour a collar before liner fitting.

Plumbing is the pool’s circulatory system. Skimmers, returns, main drains with anti-entrapment covers, and dedicated lines for features are manifolded to the equipment pad. Properly sized pipe and smooth sweep fittings reduce head loss, letting a variable-speed pump run slower and save energy. Electrical work covers bonding, grounding, and safe routing for pumps, lights, and automation under residential codes. Conduits and junctions must remain dry and accessible. Gas or heat-pump lines for heaters are installed with clearances and ventilation taken seriously.

Waterproofing and surface work are where beauty meets function. Concrete shells cure before plaster or aggregate finishes are applied; moisture content and weather drive timing. Expansion joints between pool and deck accommodate movement and protect tiles from cracking. Decking options—brushed concrete, pavers, stone, or composite surfaces—affect slip resistance, heat underfoot, and maintenance. Drainage is crucial: deck slopes should shed water away from the pool and structures, and subsurface drains may be added for heavy soils. Around the pool, barrier requirements are finalized with self-closing gates and latch heights per local rules.

Quality control reduces long-term headaches. Useful checkpoints include:

– Verify elevations and slopes before concrete or shell set.

– Pressure-test plumbing before backfill to catch leaks early.

– Confirm equipment sizing against volume and features, not just rule-of-thumb charts.

– Review bonding continuity on steel, rails, and equipment for electrical safety.

– Photograph each phase (steel, plumbing, conduit) for a future reference record.

Timelines depend on weather, inspector availability, and complexity. A straightforward fiberglass project can be completed in weeks once scheduled; concrete projects, especially with raised walls, spas, or complex coping, often run into a few months. Rain pauses excavation and finishing; cold snaps can slow cure times. Communicate with your builder about sequencing and hold points, and request a weekly update that lists completed tasks and next steps. When water flows and the pump hums quietly at low speed, those measured steps pay off in a pool that performs season after season.

Conclusion and Long-Term Value: Ownership, Maintenance, and ROI

Owning a pool is a steady rhythm of small tasks that prevent big ones. Filtration options include sand, cartridge, and diatomaceous media; each clears water effectively when sized and maintained. Cartridge systems avoid backwashing and conserve water, while sand is familiar and easy to service. Variable-speed pumps can cut electricity use significantly by circulating slowly for more hours; many households see 40–70% savings compared with single-speed operation. Heaters come in gas, heat pump, and solar-assisted formats; covers reduce heat loss and evaporation, a win for both comfort and utility bills. Expect annual energy use for circulation in the low thousands of kWh in many climates, with large features or long seasons pushing that higher.

Water balance protects finishes and equipment. Keep pH near 7.2–7.8, total alkalinity in the recommended band, and stabilize chlorine where applicable to reduce UV degradation. Brushing plaster or aggregate finishes prevents scale; vacuuming keeps fine debris from settling. Shock treatments recover clarity after heavy use or storms. A simple weekly routine often includes testing, skimming, emptying baskets, and checking the filter’s pressure. Seasonally, inspect sealants, lighting niches, and grout lines; refresh caulks and lubricate o-rings. If winterizing, lower water to the appropriate level, blow out lines, add winter chemicals, and secure a safety cover that also keeps out leaves and sunlight.

Budget realistically for ownership. Chemistry and consumables can range from a few hundred dollars to over a thousand annually, depending on pool size, climate, and chosen systems. Service visits add labor but save time; many owners blend DIY routines with annual professional checkups. As for property value, studies and market reports often show an uplift in warm regions where pools are highly valued, sometimes in the mid-single-digit percent range, while cooler markets vary more with buyer preferences and operating costs. The non-monetary return—daily recreation, family gatherings, and a private place to unwind—often drives the decision just as much as resale math.

For prospective owners, here’s a practical wrap-up to guide your next move:

– Finalize goals and non-negotiables (size, depth, features) before pricing.

– Choose a construction method that matches soil, access, and timeline.

– Lock in permits and inspections early to smooth the schedule.

– Invest in efficiency (variable-speed pump, cover, smart controls) to trim ongoing costs.

– Set a maintenance cadence and keep a seasonal checklist within reach.

If you’ve read this far, you already approach the project like a steward, not just a buyer. That mindset pays dividends: fewer surprises, calmer decisions, and a pool that reflects both your lifestyle and your landscape. Plan carefully, build methodically, and maintain with intention. The result is a dependable centerpiece for your home—one that earns its keep from the first swim through many seasons to come.