Appliance Repair Service: Professional Diagnostics and Repairs for Home Appliances

Outline:

– Why Appliance Repair Matters: Safety, Savings, and Sustainability

– How Professional Diagnostics Work: Tools, Tests, and Transparent Findings

– Repair or Replace? Decision Framework by Appliance Type

– Costs, Warranties, and Service Models: What Drives Price and Value

– Conclusion and Preventive Care: Simple Habits, Smart Hiring, Next Steps

Why Appliance Repair Matters: Safety, Savings, and Sustainability

When a refrigerator warms up or a washer thumps like a drumline, it’s tempting to rush to the store. Yet appliance repair deserves a closer look. Timely service can prevent hazards, save money, and reduce waste, turning a chaotic household moment into a manageable to-do. Major appliances are built to run for years—refrigerators commonly last 10–15, washers 8–12, dryers 10–13, and dishwashers 7–12—so a single component failure rarely means the whole machine is finished. Think of repair as preventive medicine: targeted, evidence-based, and often far less invasive than replacement.

Safety sits at the top of the list. Loose electrical connections, worn heating elements, clogged dryer vents, and brittle hoses are small problems that can create big risks. Technicians use standardized checks to spot heat damage, arcing, and leaks before they escalate. Even routine fixes add safety margins: reseating a door latch restores correct temperature control, replacing a fill valve stops a slow drip that could become a floor-warping leak, and cleaning a lint pathway reduces ignition risk. These are unglamorous wins that keep a home secure.

Repair can also be the budget-friendly path. Many issues—failed capacitors, worn belts, cracked door gaskets, or blocked drain pumps—are localized and relatively affordable, especially compared with the price and logistics of a new appliance plus delivery, haul-away, and installation. Consider the “50% rule”: if a repair costs less than half the price of a comparable new unit and the appliance is within its average life expectancy, repair is often the prudent choice. Furthermore, fixing a performance issue can restore efficiency, trimming utility bills over time.

Finally, sustainability benefits are meaningful. Repairing rather than replacing reduces material waste, lowers the carbon footprint associated with manufacturing and shipping, and keeps bulky items out of landfills. Modern parts distribution makes it practical to refresh a machine with a single component rather than discarding the entire unit. A well-executed repair transforms a problem into stewardship—of your budget, your home, and the environment.

Quick wins that underscore the value of repair:

– A misaligned refrigerator door seal corrected with a new gasket can restore cooling and stop compressor overwork.

– A dryer that squeals due to a worn idler pulley may run quietly and safely for years after a simple swap.

– A dishwasher that leaves residue often needs a filter cleaning and spray-arm unclogging, not a new machine.

How Professional Diagnostics Work: Tools, Tests, and Transparent Findings

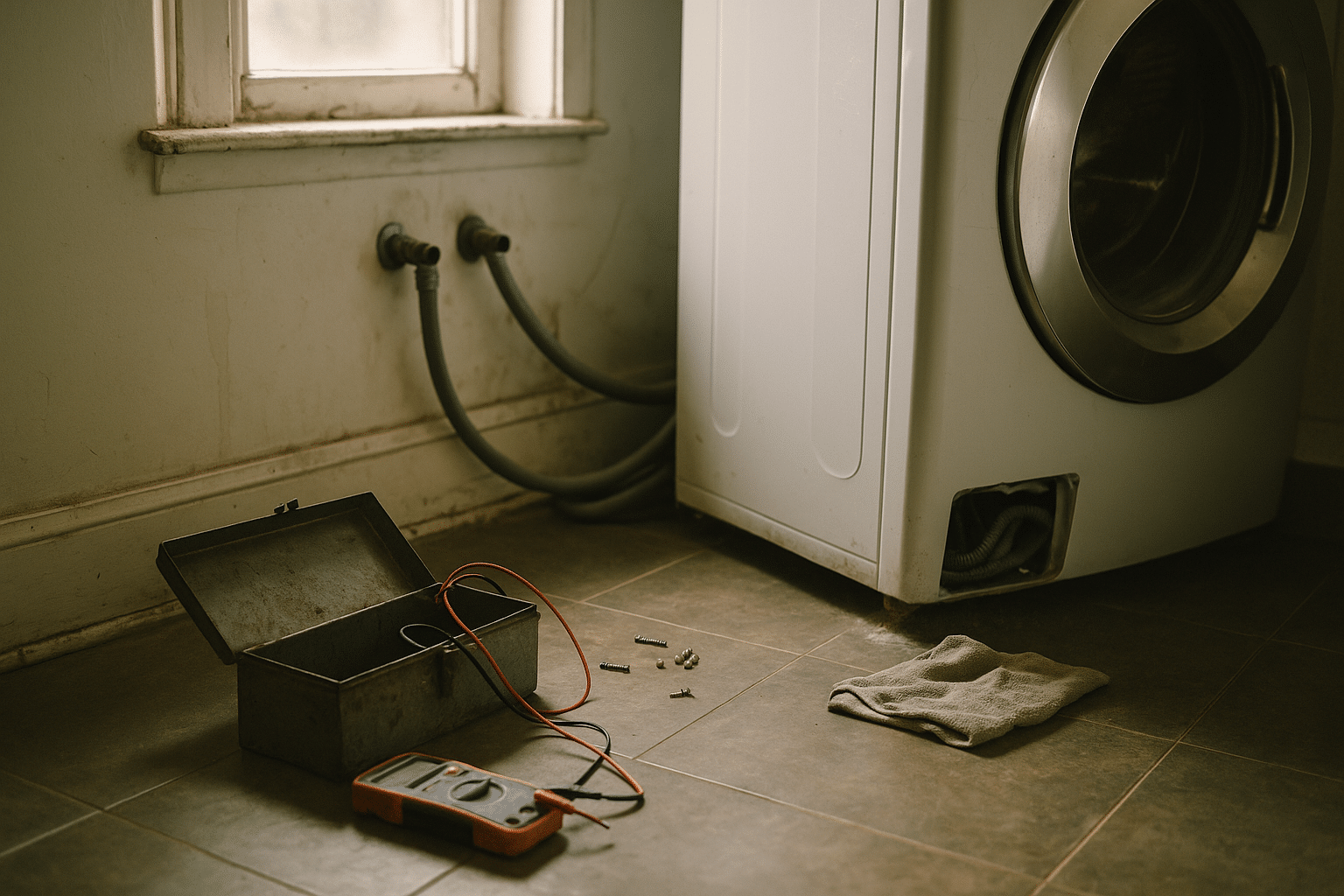

Good diagnostics are a calm conversation with a noisy machine. The process usually starts before a tool is lifted: a technician asks targeted questions about symptoms, timing, smells, sounds, and any error codes. This history narrows the field from dozens of possibilities to a manageable short list. Next comes a visual and safety inspection—checking cords, outlets, hoses, vents, gaskets, and signs of heat or water damage. Only after the basics are secure does testing begin.

Common diagnostic steps include:

– Electrical measurements with a multimeter to verify voltage, continuity, and resistance across fuses, heaters, motors, sensors, and control boards.

– Functional tests: running short cycles, measuring temperature rise, monitoring spin speed, or observing fill and drain rates.

– Airflow and pressure checks on dryers and ducting, using simple gauges to detect blockages.

– Leak tracing with dye or moisture detection near valves, pumps, and seals.

– Error-code retrieval from onboard controls when available, then confirming with physical tests rather than guessing.

Technicians rely on structured logic. For instance, a refrigerator not cooling but with interior lights on suggests power supply is intact; next, they’ll test the start device or compressor windings, inspect condenser coils, verify evaporator frost patterns, and evaluate fans. A washer that won’t drain leads to a different tree: check for foreign objects in the filter, look for a kinked hose, test the drain pump windings, and confirm the control board is sending power appropriately. Each result narrows the path toward a verified cause rather than a hunch.

Transparency should accompany every step. A clear diagnosis includes the failed component, why it failed, how the fix addresses the root cause, parts availability, lead time, and total cost. You should expect a written estimate and a simple explanation of risks—like the chance a seized bearing has also stressed the motor. Equally important is the post-repair validation: re-running cycles, measuring temperatures, checking for leaks, and confirming that error codes clear. A short, tidy functional test is the “victory lap” that proves the job is complete and your home is safe.

What you should hear from a thorough diagnostic visit:

– The suspected root cause and how it was confirmed.

– The exact part(s) to be replaced and alternatives if applicable.

– The labor time estimate and any special order considerations.

– Preventive suggestions to avoid a repeat failure.

Repair or Replace? Decision Framework by Appliance Type

Decisions are easier with a framework, and appliances reward a structured approach. Start with four anchors: age, severity, cost, and efficiency. Age matters because reliability typically declines as bearings wear, seals harden, and electronics endure thermal cycles. Severity refers to how central the failed component is—door gaskets are simple, but sealed-system work on a refrigerator is complex. Cost should include labor, parts, delivery, removal, and installation if you replace. Efficiency captures both energy and water use; newer models may offer lower operating costs, yet some midlife repairs can restore most of the original performance.

By appliance type:

– Refrigerators: Frequent culprits include fans, thermistors, defrost components, and door seals. When cooling fails due to a minor electrical component or dirty condenser coils, repair is often sensible. Sealed-system issues (compressor or refrigerant leaks) are more complex; if the unit is older and the quote is high, replacing may be practical.

– Washers: Drain pump clogs, worn belts, door lock assemblies, and inlet valves are fix-friendly. A basket bearing replacement is labor intensive and can be costlier; weigh this against the machine’s age and noise severity.

– Dryers: Broken belts, worn rollers, faulty thermostats, and clogged vents are straightforward. Heating elements are replaceable, but heavy rust, repeated high-heat cutoffs, or a damaged drum may tip the scale toward replacement.

– Dishwashers: Circulation pumps, diverter valves, float switches, and door latches are common repairs. Tub cracks or persistent, undiagnosed leaks into cabinetry often argue for replacement to prevent ongoing damage.

– Ovens and ranges: Igniters, bake/broil elements, thermostats, and door hinges are generally repairable. Gas leak concerns or extensive corrosion can complicate the equation and may justify upgrading.

A practical rule of thumb brings it together: if the repair is under 50% of a comparable new unit and the appliance is within its average lifespan, repair typically makes sense. Exceed 50%, or approach the far end of the lifespan, and replacement deserves a serious look—especially if you can gain quieter operation or lower utility costs. Always review the whole-home picture, too: consolidating multiple minor issues into one service visit saves travel and diagnostic fees and minimizes disruption.

Scenario snapshots:

– A 6-year-old washer with a failed drain pump: replacement part and labor are moderate, and the machine is midlife—repair favored.

– A 12-year-old dishwasher with repeated leaks: risk to cabinetry is high, and efficiency gains from newer units can be meaningful—replacement favored.

– A 9-year-old refrigerator with a failed evaporator fan: part and labor are reasonable, and temperature control is restored—repair favored.

Costs, Warranties, and Service Models: What Drives Price and Value

Understanding pricing removes the mystery from repair quotes. Most services break costs into a diagnostic fee, labor rate, parts, and incidentals like trip charges. Diagnostic fees compensate for the time and expertise needed to identify faults; many providers credit this fee toward the repair if you proceed. Labor rates reflect technician skill, insurance, vehicle and tool costs, and local market conditions. Parts pricing varies with the component’s complexity, sourcing (original-equipment versus compatible), and current supply chain dynamics.

What influences your final bill:

– Appliance location: Tight laundry closets and stacked installs increase labor time.

– Fast-track requests: Same-day or evening service can carry a premium.

– Rust and corrosion: Seized fasteners and stuck components extend disassembly time.

– Multiple issues: Bundling fixes in one visit reduces repeat trip charges and downtime.

Warranties are a signal of confidence. Many providers offer separate coverage windows for parts and labor—commonly 30–90 days for labor and longer for parts, depending on the component and supplier. Clarity matters more than length: you want the terms in writing, including what voids coverage (e.g., flood damage or unauthorized tampering). If a high-value component is replaced, ask about extended coverage options and whether preventive steps—such as cleaning condenser coils or replacing water hoses—are required to keep the warranty intact.

Service models differ, and the right fit can save time and money:

– In-home repair: Convenient and ideal for large appliances; minimizes risk from moving heavy units.

– Carry-in shop repair: Suitable for compact appliances; often lower trip costs.

– Mobile inventory vans: Faster turnaround for common parts, reducing delays.

– Maintenance plans: Periodic inspections and cleanings that catch early wear and keep efficiency on track.

Value isn’t just price; it’s predictability and professionalism. Look for written estimates, itemized parts and labor, proof of insurance, and punctual communication. Red flags include vague diagnostics (“probably the board”), open-ended pricing with no cap, and reluctance to provide documentation. On the positive side, a well-regarded service will explain options, respect your budget, and leave a tidy workspace—small details that add up to trust.

Cost-savvy tips:

– Combine appointments for multiple appliances to spread the diagnostic fee.

– Approve parts only after you understand availability and return policies.

– Ask whether an upgraded part (for example, a redesigned seal) reduces repeat failures.

Conclusion and Preventive Care: Simple Habits, Smart Hiring, Next Steps

Repairs restore calm, but prevention preserves it. A handful of small habits can radically reduce breakdowns and energy waste. Clean refrigerator condenser coils twice a year to lower compressor load. Replace rubber washer hoses every 5–7 years with reinforced lines to reduce burst risk. Empty the washer’s filter and run a maintenance cycle monthly if you do frequent laundry. Clear the dryer lint screen every load and have the vent pathway inspected annually, especially if the duct run is long or has multiple bends. Check dishwasher filters and spray arms monthly to maintain water pressure and cleaning performance. Inspect door gaskets on all appliances: a thin film of mild cleaner on a cloth keeps seals supple and leak-resistant.

Preventive checklist you can do in under an hour:

– Refrigerator: Vacuum coils, verify door closes smoothly, and keep a few inches of airflow around the unit.

– Washer and dryer: Level the machines to reduce vibration; confirm the dryer vent has strong, warm airflow outside.

– Dishwasher: Clean filter and run a hot cycle with a descaling agent if your water is hard.

– Range/oven: Wipe spills promptly to prevent baked-on residue from stressing burners or elements; check for even flame or element glow.

Smart hiring makes the next breakdown less stressful. Before booking, ask about licensing, insurance, and how estimates are structured. Request a brief outline of the diagnostic process so you know what happens on arrival. Clarify parts sources and warranty terms in writing, and ask what the post-repair test will include. A transparent, highly rated provider is comfortable sharing this information and offering practical prevention advice tailored to your appliances and usage patterns.

As you act, use the decision framework: weigh age, severity, cost, and efficiency. If the repair is modest and the appliance is midlife, repair often delivers outstanding value. If the quote climbs and the machine is late in its lifespan, replacement can bring quieter operation, better energy use, and fresher safety features. Either way, you’re not just fixing metal and plastic—you’re restoring the rhythm of daily life. Keep this guide handy, schedule routine maintenance, and you’ll spend more time enjoying clean dishes, fresh clothes, and even temperatures—and far less time chasing error codes.