Learn about Solar Panels

Why Solar Panels Matter + Article Outline

Outline of what you’ll learn:

– How photovoltaic modules turn sunlight into electricity

– A comparison of major technologies and what efficiency numbers actually mean

– Costs, incentives, financing paths, and realistic payback windows

– Site assessment, design choices, and grid integration basics

– Long-term care, reliability, recycling, and a practical conclusion for homeowners and small businesses.

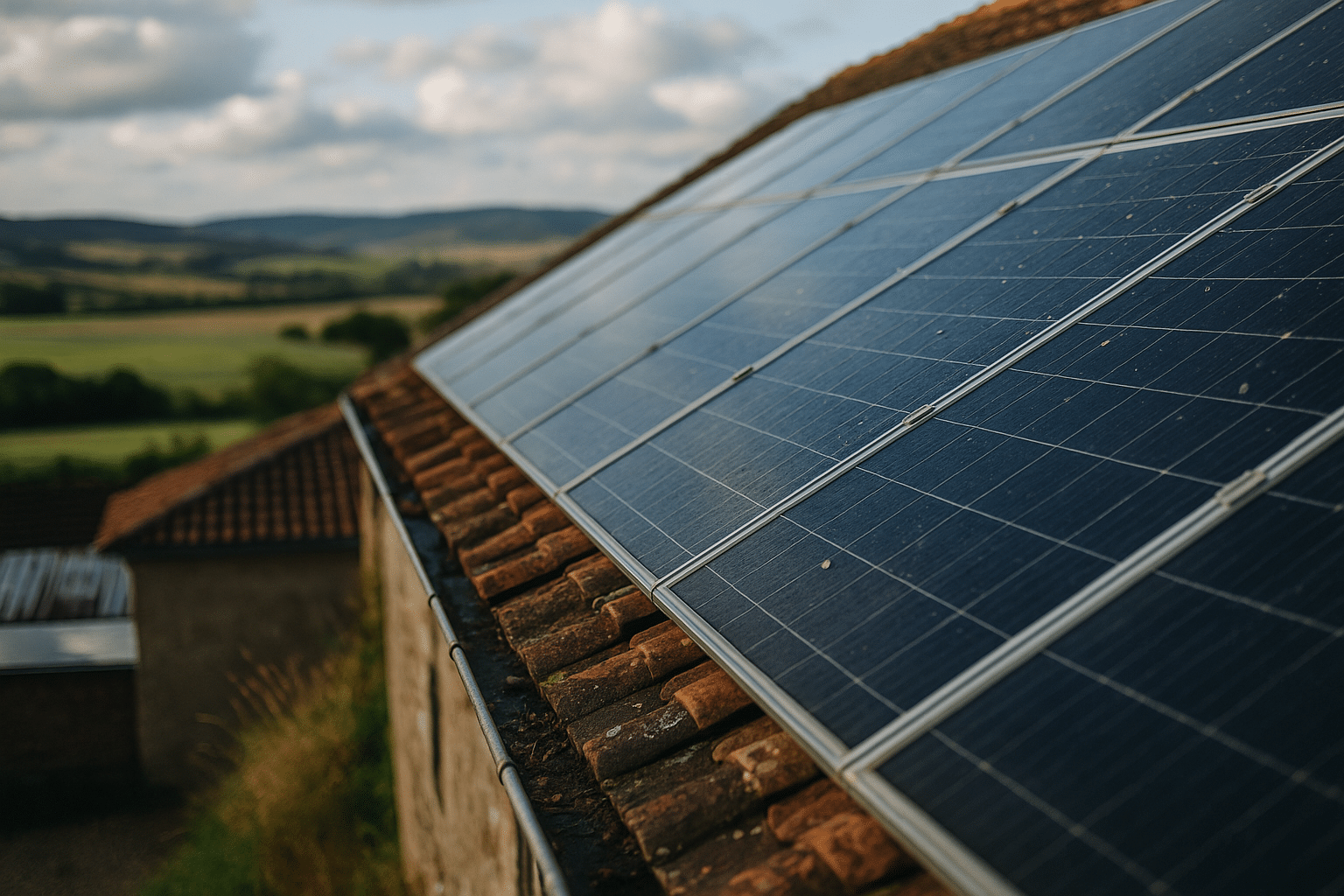

Solar panels have moved from niche tech to mainstream power source, with cumulative global capacity well past the terawatt mark and growing rapidly year over year. What makes them compelling is a blend of declining hardware costs, stable fuel (sunlight), and a track record of dependable performance over decades. For many households and small organizations, solar offers a way to hedge against energy price swings while shrinking operational emissions. Typical residential modules convert roughly 18–23% of sunlight into electricity today, and rooftop systems can offset thousands of kilowatt-hours annually depending on location and roof conditions.

Equally important is the local angle: each property has unique shading, roof geometry, and electrical needs. That means the “right” system is rarely one-size-fits-all. In the pages ahead, you’ll see how to interpret efficiency figures, weigh equipment choices, and estimate production without guesswork. You’ll also learn about common policy tools—like net metering or smart export rules—and how incentives, rebates, and tax credits can change the math. The goal is clear, actionable guidance that treats your roof, your budget, and your climate with the care they deserve.

To make it easy to navigate, this guide follows the outline above. We begin with how solar works and why different module types perform differently across climates. Then we look at costs, financing, and payback with simple, transparent math. Next comes site assessment and system design, including roof structure, tilt, and grid interconnection. Finally, we close with maintenance, reliability over time, recycling pathways, and a grounded conclusion you can use to make a confident decision.

How Solar Panels Work: From Sunlight to Usable Power

At the heart of a solar panel is the photovoltaic effect: certain materials (commonly silicon) release electrons when energized by photons. A panel strings many solar cells together to produce direct current (DC) electricity, which flows to an inverter that converts it to alternating current (AC) suitable for home circuits and the grid. The core performance metric for a panel is efficiency—the fraction of sunlight that becomes electricity under standardized test conditions. Today’s mainstream monocrystalline modules often land in the 20% neighborhood, while some thin-film variants trade peak efficiency for advantages like better high-temperature behavior or flexible form factors.

Temperature, angle, and shading matter. As panels heat up under sun, output drops slightly; a typical temperature coefficient might be around −0.3 to −0.4% per °C above 25°C. Proper airflow under the array helps, as does choosing equipment with favorable coefficients in hot climates. Shading has a disproportionate effect because cells are electrically interconnected; even a small shadow can throttle current through a whole string. Bypass diodes mitigate this, and power electronics (like module-level devices) can further reduce shade losses.

A quick comparison of common technologies:

– Monocrystalline silicon: higher efficiency, compact footprint, solid cold-weather performance.

– Multicrystalline silicon: slightly lower efficiency, often cost-effective for ample roof space.

– Thin-film (such as amorphous or compound semiconductors): lower peak efficiency on average but can offer lighter weight, uniform aesthetics, and resilient temperature behavior.

– Bifacial designs: harvest light from the front and reflected light from the rear, adding a performance lift when mounted over bright surfaces.

System architecture choices shape reliability and energy yield. String inverters are simple and well-proven, typically serving a group of panels wired in series; they often pair with DC optimizers for shade management. Module-level inverters decentralize conversion, offering panel-by-panel monitoring and resilience to partial shading. Either path can be engineered to high standards—what matters is matching the approach to roof geometry, shade patterns, maintenance preferences, and budget. Finally, balance-of-system details—racking, wiring, combiner boxes, rapid shutoff devices, and monitoring—round out the system, each contributing to safety, code compliance, and long-term performance.

Costs, Incentives, and Payback: Making the Numbers Work

Upfront cost is typically quoted per watt of direct-current capacity. Residential installed prices frequently land in the range of about 2–4 currency units per watt, depending on local labor costs, permitting, roof complexity, and equipment choices. A 6 kW system, for instance, might be priced around 12,000–24,000 before incentives. Annual production varies widely by location: from roughly 900–1,100 kWh per kW in cloudier regions to 1,400–1,700 kWh per kW in sunnier climates. Using 1,300 kWh per kW as a mid-range example, a 6 kW system could generate about 7,800 kWh per year.

Revenue or savings depends on your tariff. If your retail electricity price is 0.18 per kWh and net metering is available, that 7,800 kWh might offset around 1,400 per year before fixed charges. Where feed-in rates or smart export tariffs apply, export value may differ from import prices, which changes payback math. Incentives come in several forms:

– Upfront rebates that lower capital cost

– Tax credits that reduce tax liability on a percentage of project cost

– Accelerated depreciation for qualifying businesses

– Low-interest loans, leases, or power purchase agreements to spread payments

As a blended view, many homeowners see simple paybacks in the 6–12 year window, though results can be faster in high-rate regions or slower where sun is scarce and incentives are minimal. Levelized cost of energy (LCOE) for a well-sited rooftop system can compare favorably with retail rates, particularly when financing costs are kept moderate and soft costs (permitting, interconnection, inspections) are managed efficiently. Two quick rules of thumb:

– Higher self-consumption improves economics under export-limited policies.

– Modest oversizing relative to daytime loads pairs well with future electrification (EV charging, heat pumps) without stranding capacity.

It’s wise to model scenarios. Run a base case with conservative production (for example, 1,200 kWh per kW) and a cautious degradation rate (0.5–0.7% per year). Add a sensitivity check for tariff changes and shade losses. If storage is on the horizon, include it as a separate line item with its own cycle life and round-trip efficiency. Clear, realistic estimates prevent surprises and help you compare offers consistently, using the same assumptions and time horizon.

Site Assessment, Design Choices, and Grid Integration

Good design starts with the roof and the sun. In the northern hemisphere, south-facing arrays with tilt angles near local latitude often maximize annual yield, while east–west layouts can spread production over morning and afternoon to match household demand. In the southern hemisphere, reverse the compass guidance accordingly. Shading analysis—by season and hour—matters more than almost any other single factor; a chimney casting a shadow at noon in winter can reduce output far beyond its apparent footprint. Aim for consistent sun during peak hours, and consider module-level power electronics if trees or nearby buildings are unavoidable.

Structural and environmental factors shape racking and attachment choices. Typical dead loads for flush-mounted arrays fall in the range of 2–6 lb/ft² (10–30 kg/m²), which most modern roofs can handle when in good condition; still, aging rafters, brittle tiles, or corroded metal roofs deserve a careful look. Wind and snow loads set by local codes drive rail spacing, attachment count, and edge setbacks. Fire codes may require clear aisles near ridges and hips for access. A thorough site visit usually captures:

– Roof age and condition, including underlayment

– Rafter layout and anchoring points

– Obstructions like vents, skylights, and satellite hardware

– Conduit paths to the main service panel and meter

– Grounding, bonding, and rapid shutoff device placement

On the electrical side, decide whether the system will be grid-tied, off-grid, or hybrid with storage. Grid-tied systems without batteries are the simplest and most common, exporting excess energy during the day and importing at night. Hybrid systems add batteries to shift solar generation into evening peaks or to provide backup power during outages; off-grid designs rely fully on storage and supplemental generation (such as a small generator) to handle extended cloudy periods. Interconnection typically requires an application, a one-line diagram, and an inspection; some utilities set export limits or require smart inverters that adjust voltage and frequency support for grid stability.

Finally, think ahead to future loads. If you plan to adopt electric vehicles or replace a gas furnace with a heat pump, wire conduits and breaker space now, even if the array is installed in stages. This “pre-wire” strategy costs little during the initial build but avoids messy retrofits later. Clear labeling, robust wire management, and accessible monitoring hardware make for an installation that’s not just productive on day one, but easier to maintain for decades.

Long-Term Care, Reliability, Recycling, and Conclusion

Once installed, solar arrays ask very little. Most sites see minor soiling losses, often in the 2–5% range; occasional rain may be enough for cleaning, though dry, dusty climates can benefit from a gentle rinse with deionized water during cool hours. Snow typically sheds from glass surfaces as the sun warms the modules, but angled arrays and a smooth lower edge help. A typical performance warranty guarantees output will remain above a stated percentage (commonly around 80–85%) after 25 years, reflecting modest degradation rates of roughly 0.3–0.8% per year. Inverters and batteries have shorter lifecycles—budget for an inverter replacement around year 10–15 for many systems, and follow manufacturer guidance on ventilation and temperature limits for storage.

Monitoring is your quiet ally. Systems with per-panel or per-string data make it easier to spot anomalies like a tripped breaker, a shaded branch that grew faster than expected, or an underperforming circuit. Maintenance checklists often include:

– Visual scan of wiring, roof attachments, and seals once a year

– Confirmation of torque on accessible fasteners after the first season and then periodically

– Review of monitoring trends after storms or extreme heat events

– Coordination with a qualified electrician for any issues inside service equipment

End-of-life planning is improving rapidly. Most modules are predominantly glass and aluminum, with small amounts of polymers and semiconductors; those materials are increasingly recoverable through established or emerging recycling streams. Some regions have producer responsibility programs that fund collection and processing, and more recyclers now accept crystalline silicon and thin-film panels. Energy payback time—the period a system needs to generate the energy invested in its manufacture—has fallen to roughly 1–3 years in many climates, leaving decades of net-positive energy thereafter, assuming typical lifespans.

Looking ahead, new cell architectures and tandem designs are pushing efficiencies upward without sacrificing durability, while building-integrated products and agrivoltaic layouts are expanding where panels can live—on facades, over parking areas, and alongside crops. None of this changes the fundamentals: careful siting, conservative financial assumptions, and clean workmanship remain the pillars of a satisfying project. Conclusion for homeowners and small businesses: define your goals (bill savings, resilience, emissions), get a site-specific production estimate, compare a few clear proposals on the same terms, and choose the configuration that aligns with your roof and your plans for electrification. With that approach, solar becomes a steady, comprehensible asset that earns its keep quietly, day after day.